Rice Cleaning Machines: Efficiency in Cleaning, Quality in Production

22 Eylül 2025Quality and productivity in agriculture are directly related to the technological proficiency of the equipment used. Choosing the right equipment is crucial, especially when processing demanding crops like paddy rice. In this regard, paddy rice cleaning machines provide producers with significant convenience and high efficiency. Advanced paddy rice cleaning machines increase purity in the paddy rice processing process while minimizing product loss.

What are paddy rice cleaning machines?

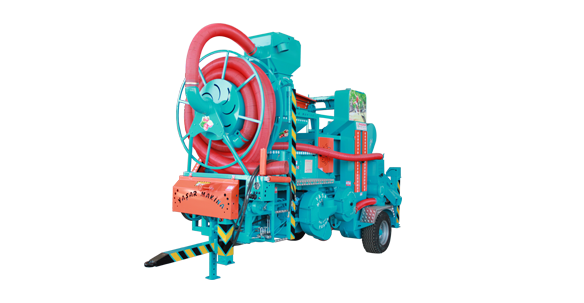

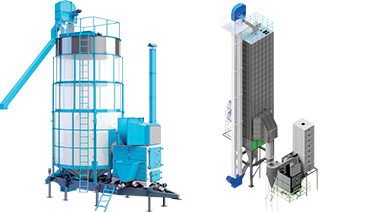

Paddy rice cleaning machines are specialized agricultural machines that separate foreign materials (stones, straw, dust, and light particles) from paddy rice after harvest. These machines have become an indispensable part of paddy rice processing facilities. Modern paddy rice cleaning machines offer significant advantages to producers by consuming minimal energy while operating at high capacity.

Why Use Paddy Rice Cleaning Machines?

• High Cleaning Rate: High-quality paddy rice cleaning machines provide purity levels of up to 99%.

• Time and Labor Saving: They are much faster than manual cleaning processes.

• Increased Product Quality: Well-cleaned paddy rice commands a higher sales value.

• Energy Efficiency: New-generation paddy rice cleaning machines offer high performance with low energy consumption.

• Minimum Waste: Increases productivity by reducing product loss.

How Do Paddy Rice Cleaning Machines Work?

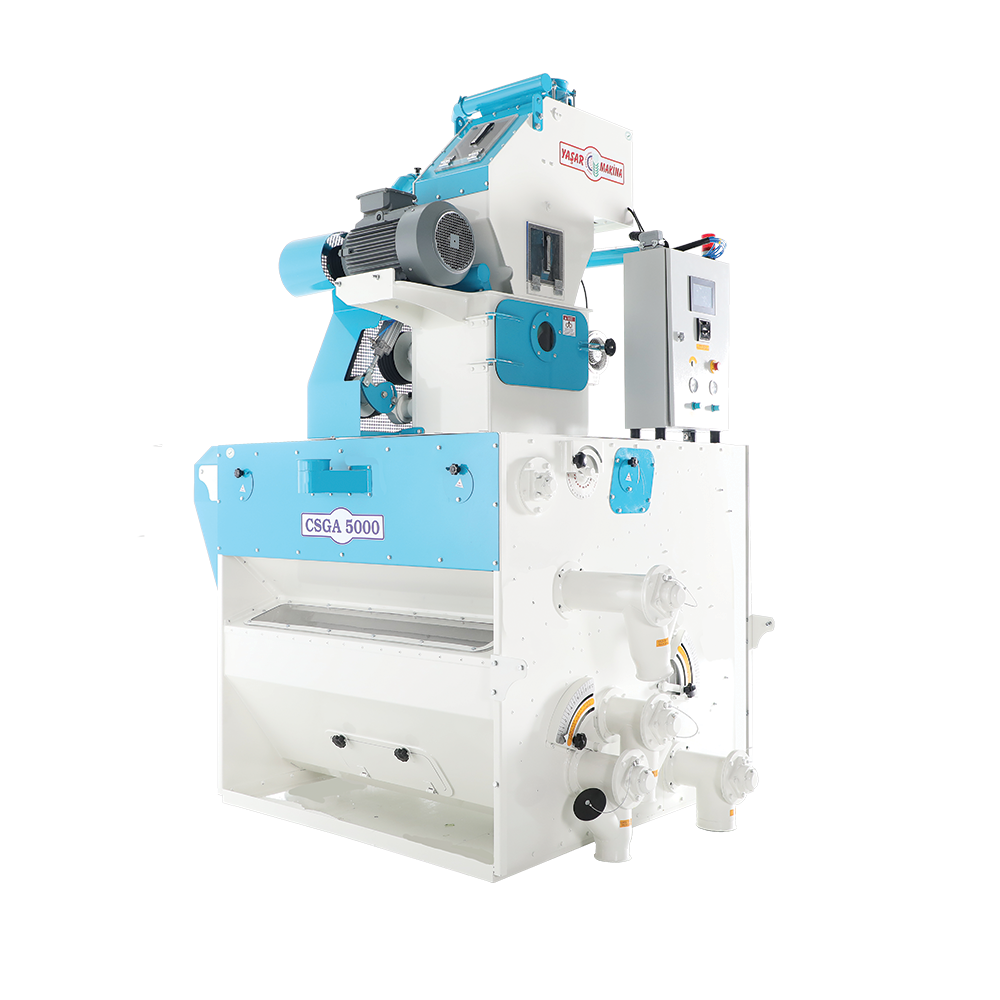

Paddy Rice Cleaning Machines operate using various screening systems, air blowing mechanisms, and vibrating platforms. While foreign materials are separated, intact paddy rice grains are cleaned without damage. Thanks to automatic adjustment systems, paddy rice cleaning machines easily adapt to different types of paddy rice.

What to Consider When Choosing Paddy Rice Cleaning Machines?

1. Capacity: Hourly cleaning capacity should be appropriate for your production volume.

2. Machine Size: Choose paddy rice cleaning machines sized appropriately for your area.

3. Material Quality: A stainless steel body and robust construction ensure long-lasting use.

4. Service and Support: Prioritize brands that offer easy spare parts availability and technical support.

5. Energy Consumption: Low-energy paddy cleaning machines reduce operating costs.

Paddy Cleaning Machines Preferred in Turkey

Many businesses operating throughout Turkey increase their productivity with domestically produced paddy cleaning machines. These machines are widely used in regions where paddy production is concentrated, particularly in Thrace and the Black Sea region. Domestically produced machines offer both cost advantages and ease of technical support.

Paddy Cleaning Machine Prices

Paddy cleaning machine prices vary depending on capacity, material quality, and technological features. While high-quality and durable machines generally cost a bit more upfront, they yield greater returns in the long run. Choosing the right paddy cleaning machine for your business's needs provides a significant advantage.

The Goal with Paddy Cleaning Machines: Clean Product, High Returns

It's important to remember that cleaned products are easier to sell both domestically and in export markets. This highlights the importance of using paddy cleaning machines not only for production but also for marketing. Professional machines can also be used to clean crops such as corn, wheat, and barley.

Conclusion: Investing in the Future – Rice Cleaning Machines

Quality production begins with quality equipment. Therefore, rice cleaning machines are essential for anyone looking to invest in the future of agriculture. If you want to save time and money, achieve high efficiency, and ensure customer satisfaction, rice cleaning machines are the right choice.