Efficient and High-Quality Production is Possible with Rice Separating Machines

22 Eylül 2025One of the most essential pieces of equipment for businesses seeking to improve quality and productivity in the agricultural sector is undoubtedly the Rice Separator Machine. Developed specifically for the efficient processing of raw materials in rice production, Rice Separator Machines are widely used by both domestic and international producers.

What are Paddy Separating Machines?

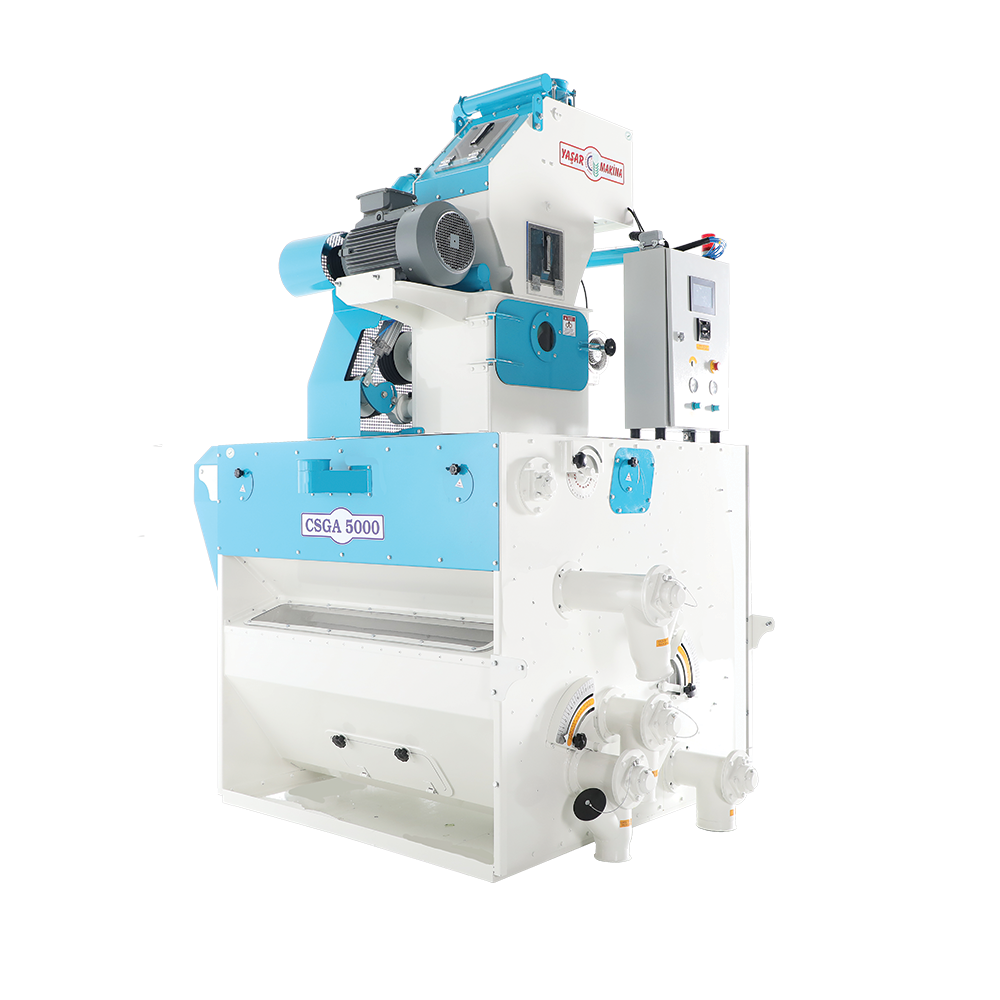

Paddy Separating Machines are high-tech systems used to separate paddy from its husk and classify high-quality products from low-quality ones. These machines easily separate unwanted paddy pieces, husks, and other waste materials from the production line.

What are the Benefits of Paddy Separating Machines?

• They separate paddy from its husk.

• They separate broken grains from healthy grains.

• They classify light and heavy grains.

• They remove foreign materials.

• They ensure products that meet high quality standards.

Paddy Separating Machines perform all these processes automatically, significantly saving time and labor.

Why Use Paddy Separating Machines?

1. High Precision: The separation process is performed with millimeter accuracy.

2. Automatic System: Minimizes labor requirements.

3. Product Quality: Improves the quality of the final product.

4. Energy Efficiency: New-generation Paddy Sorting Machines consume less energy.

5. Longevity: Their stainless steel and durable body structure offer long-term use.

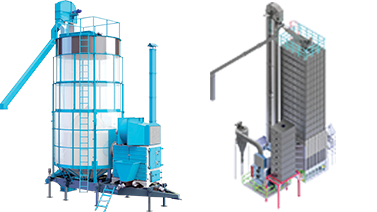

Paddy Sorting Machine Models

There are many Paddy Sorting Machine models on the market, catering to different capacities and areas of use. Some of these include:

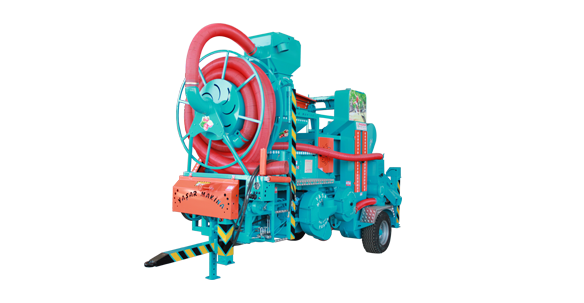

• Vibrating Paddy Sorting Machines

• Air-Powered Paddy Sorting Machines

• Cylindrical Paddy Sorting Machines

• Heavy and Light Grain Separators

• Combined Paddy Sorting Systems

Each model should be selected specifically for the needs of the business and installed with professional support.

Things to Consider When Selecting Paddy Sorting Machines

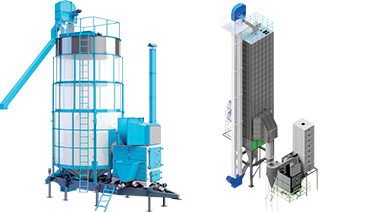

• Capacity: Hourly processing capacity should be appropriate for production volume.

• Size and space requirements: Compatibility with the facility is important.

• Access to technical support and spare parts

• User-friendly interface and easy maintenance

• Quality analysis based on domestic or imported product preferences

Using Paddy Sorting Machines in Turkey

Paddy production is widespread in regions of Türkiye such as Thrace, Samsun, and Çukurova. Most businesses operating in these regions prefer Paddy Sorting Machines for high-quality and efficient production. Paddy Sorting Machines provide effective results in both large-scale factories and small agricultural enterprises.

Paddy Sorting Machine Prices

Paddy Sorting Machine prices vary depending on capacity, model, manufacturer, and additional features. However, with the right investment, these machines quickly recoup their costs and provide long-term profits for the business.

Standardize Quality with Paddy Sorting Machines

For companies seeking to increase their competitiveness in modern agriculture, Paddy Sorting Machines are not just equipment; they also represent quality assurance. If you want to improve the quality of your products, differentiate yourself in the market, and streamline your business processes, Paddy Sorting Machines will be your most important tool.

Conclusion: The Key to a Smart Investment – Paddy Sorting Machines

Paddy Sorting Machines are an indispensable technology for all businesses seeking to improve food safety, efficiency, and quality. If you want to keep up with modern production processes and improve your product quality, explore our Paddy Sorting Machine solutions now.

Paddy Sorting Machines are a powerful step that will propel you into the future with the right investment.