Take Your Production to the Next Level with Nut Processing Machines

22 Eylül 2025Hazelnuts are one of Türkiye's most important agricultural products and hold a large share of the global market. However, the economic value of hazelnuts depends on proper processing. Therefore, hazelnut processing machines are indispensable equipment for high-quality and efficient production. These technologically advanced hazelnut processing machines automate the entire process, from shelling the hazelnuts to roasting.

What is Hazelnut Processing Machinery?

Hazelnut processing machines are integrated systems that perform processes such as cracking, sorting, roasting, grinding, and packaging hazelnuts. Used in many areas, from agricultural enterprises to large industrial facilities, hazelnut processing machines both save time and improve product quality.

What are the uses of Hazelnut Processing Machinery?

• Cracking and shelling

• Peeling the hazelnut skin

• Roasting and drying

• Sorting and sorting

• Grinding and crushing

• Vacuum packaging

All these processes are carried out automatically and hygienically with hazelnut processing machines. This reduces labor costs and ensures standardization in production.

Why Choose Hazelnut Processing Machines?

1. Time Saving: Results are achieved much faster than manual labor.

2. Hygienic Production: Ensures a high standard of food safety.

3. Increased Quality: Undamaged and evenly roasted hazelnuts are obtained.

4. Energy Efficiency: New-generation hazelnut processing machines perform more work with less energy.

5. High Capacity: Hourly production volume increases significantly.

Types of Hazelnut Processing Machinery

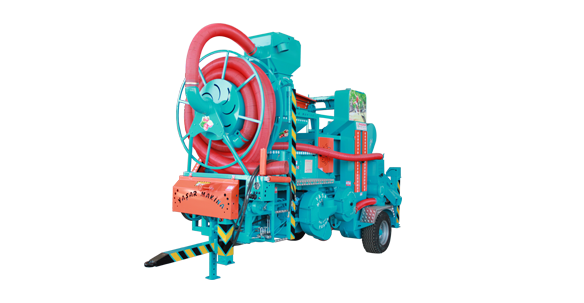

• Hazelnut cracking machines

• Shell separating systems

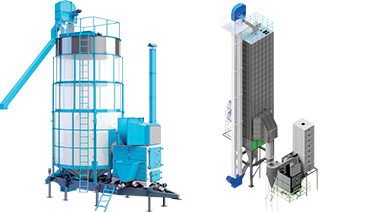

• Roasting ovens

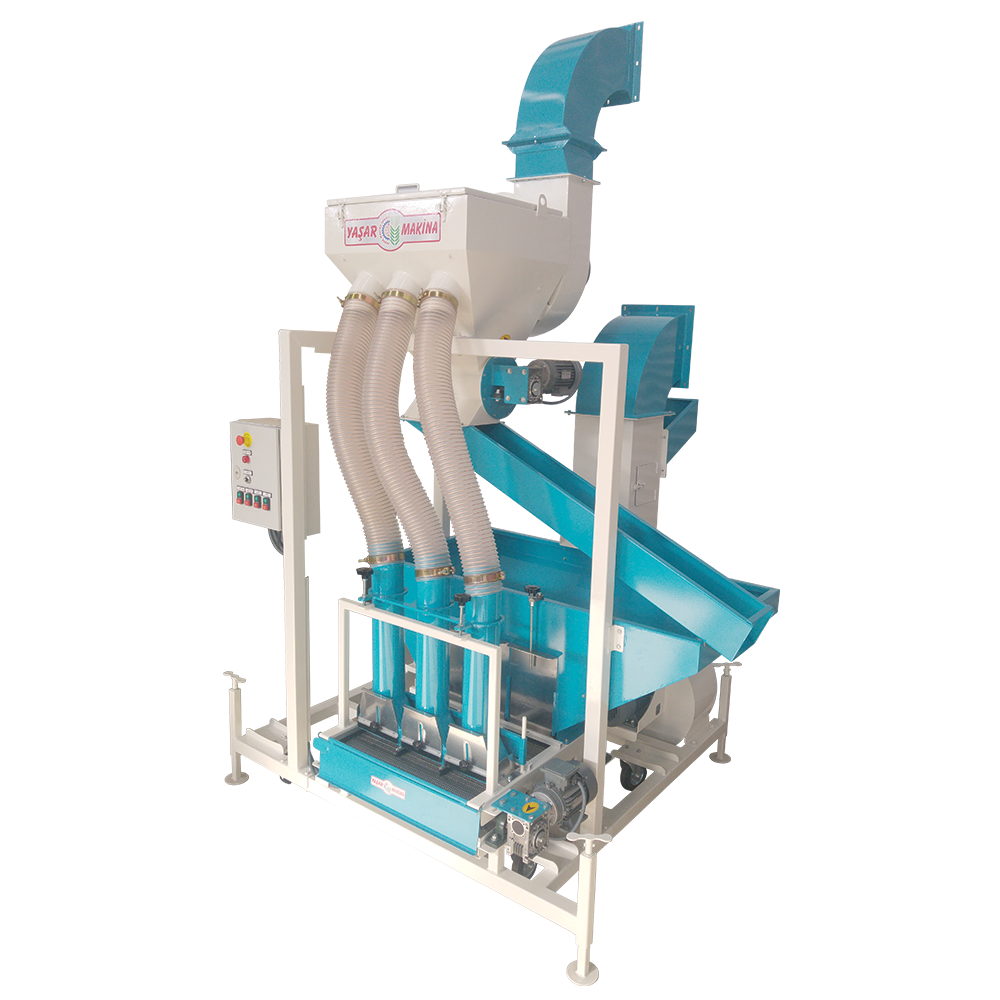

• Hazelnut sifting and grading machines

• Automatic packaging systems

• Crushing and grinding machines

Each machine has a specific function in the production chain and, when used together, provides full automation. All Hazelnut Processing Machinery can be customized to meet different business needs.

Things to Consider When Selecting Hazelnut Processing Machinery

• Machine Capacity: Selection should be made according to the hourly processing volume.

• Energy Consumption: Choose models that provide energy savings.

• Material Quality: Stainless steel should be preferred for food contact.

• Automation Level: Choose systems that require less manpower.

• Technical Support: Choose brands that offer spare parts and service.

Use of Hazelnut Processing Machinery in Turkey

Hazelnut Processing Machinery, widely used in the Black Sea region of Turkey, is used with high efficiency in both cooperatives and private facilities. Hazelnut Processing Machines, developed by domestic manufacturers, are also preferred by exporting businesses.

Hazelnut Processing Machine Prices

Hazelnut Processing Machine prices vary depending on capacity, number of functions, and technical equipment. However, they represent a long-term source of profit for every investor. With low operating costs and high production capacity, hazelnut processing machines quickly recoup their investment.

Increase Productivity with Hazelnut Processing Machines

Modern hazelnut processing machines make your production process more systematic and error-free. Traditional methods reduce quality and lead to wasted time and labor. However, automatic hazelnut processing machines both improve quality and enhance your business's competitiveness.

________________________________________

Conclusion: Increase Your Earnings with Hazelnut Processing Machines

If you value quality, speed, and profitability in hazelnut production, hazelnut processing machines are the right choice for you. With high-tech, user-friendly, and energy-efficient hazelnut processing machines, you can propel your business into the future.

Professionalize your production, raise your quality standards, and take your place in the global market with hazelnut processing machines.