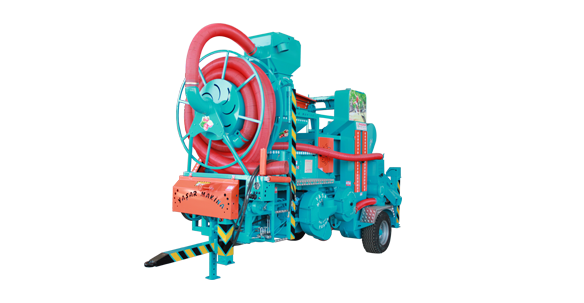

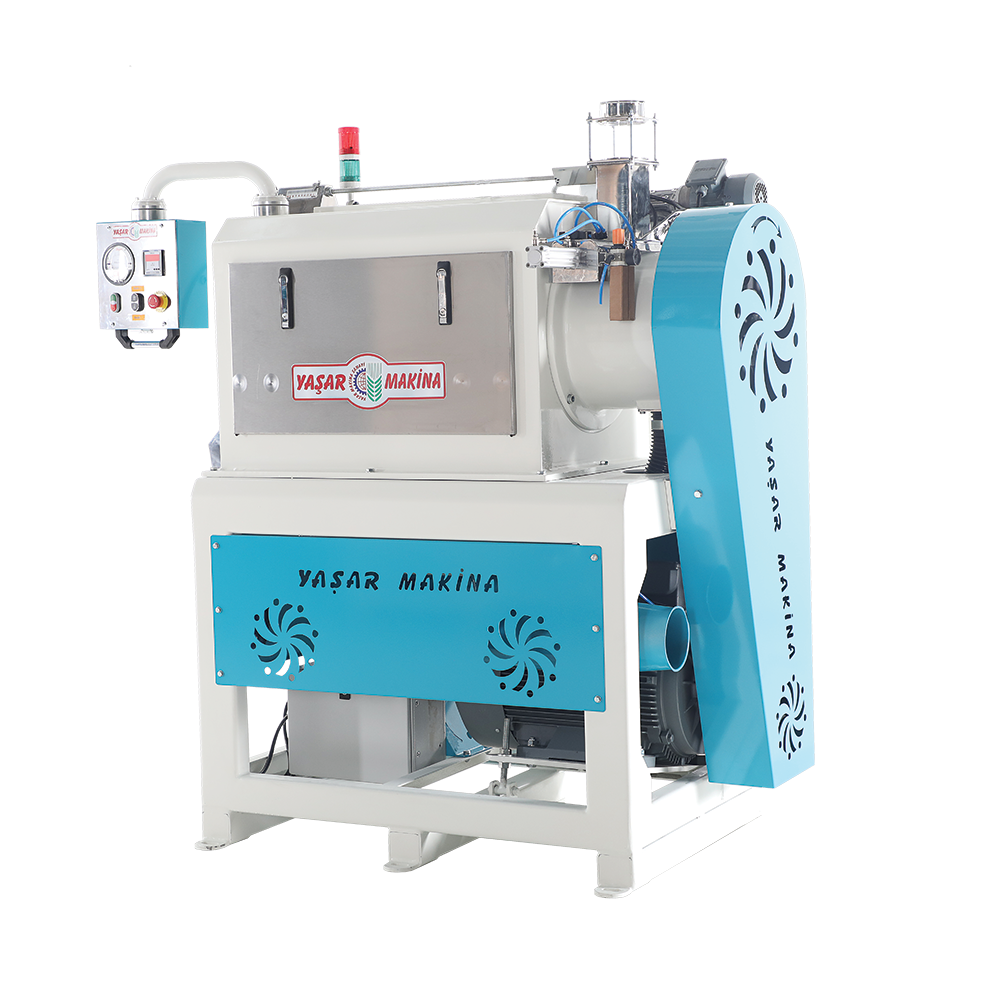

Rice Polishing Machines: The New Name for Quality and Efficiency in Industry

22 Eylül 2025Brass polishing machines are an indispensable technology for improving quality and visual aesthetics in both industrial production and small businesses. Today, brass polishing machines ensure brass surfaces are shiny, clean, and uniform, while also accelerating the production process.

Brass polishing machines used in industry save time with their high performance during production. Polishing brass, especially for decorative items, faucets, automotive components, and plumbing equipment, directly impacts product quality. This is precisely where brass polishing machines come into play.

Why Brass Polishing Machines?

• High-quality results: Brass polishing machines eliminate surface dullness and imperfections, achieving a perfect shine.

• Time and labor savings: Compared to manual polishing processes, brass polishing machines significantly reduce production time.

• Fewer errors, more efficiency: Automatic brass polishing machines minimize human error.

Where Are Brass Polishing Machines Used?

Brass polishing machines are widely used in many sectors. Most preferred areas:

• Faucet and bathroom fixture production

• Decorative goods manufacturing

• Electrical and lighting industry

• Furniture accessories production

• Agricultural tools and machine parts production

In these areas, brass polishing machines enhance both the visual and functional quality of the product.

Things to Consider About Brass Polishing Machines

The most important factors to consider when purchasing a brass polishing machine include machine power, drum size, energy consumption, and ease of maintenance. High-quality brass polishing machines are manufactured from durable materials for long-lasting use.

In addition, occupational safety should be taken into account when using brass polishing machines. Modern machines are equipped with automatic stop systems, prioritizing user safety.

Brass Polishing Machines and Automation

With developing technology, brass polishing machines can now operate integrated with automation systems. This ensures full compatibility with production lines and makes polishing processes much more efficient. CNC-controlled brass polishing machines offer precise adjustments and repeatable quality.

Why Work with Us?

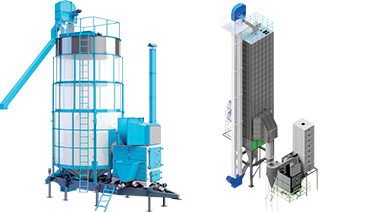

Our company has been leading the industry in the production and sales of rice polishing machines for many years. With our extensive product range, technical support, and spare parts warranty, we offer our customers a seamless experience.

We offer the perfect solution for your production line with rice polishing machine designs tailored to your needs. Both our standard models and customized machines are designed to increase your business's efficiency.

________________________________________

Improving your business's quality and streamlining your production process with rice polishing machines is now easy! Contact us for detailed information and a quote.

Quality, speed, and safety... All in one, only possible with rice polishing machines!