Increase Efficiency and Quality with Grain Drying Machines

22 Eylül 2025Grain dryers are one of the most critical pieces of equipment in the agricultural sector. In modern agricultural practices, the first step in achieving high-quality, long-lasting products is a proper drying process. High-performance grain dryers are at the heart of this process.

Today, producers of all sizes use grain dryers to minimize post-harvest product loss and extend storage. Grain dryers are indispensable for reducing moisture content to the desired level, improving product quality, and making them suitable for sale.

What are Grain Dryers?

Grain dryers are professional machines that dry grains such as wheat, corn, barley, rice, and oats by evaporating excess moisture in a controlled manner. These machines protect the product from risks such as mold, spoilage, or rot during storage.

Grain dryers have become a vital tool for producers, especially in humid regions and during peak harvest periods.

Advantages of Grain Dryers

1. High Efficiency: Saves time by drying large quantities of product in a short time.

2. Energy Savings: New-generation grain dryers offer maximum performance with low energy consumption.

3. Product Quality: They preserve the nutritional value of the product and dry it without altering its color or odor.

4. Long-Term Storage: Properly dried grain can be stored for extended periods without spoiling.

5. Economic Contribution: Higher quality, intact grain can be sold at a higher price in the market.

Where Are Grain Dryers Used?

• Agricultural cooperatives

• Private farms

• Commercial agricultural businesses

• Food production facilities

• Seed companies

Grain dryers used in these areas appeal to both small and large-scale businesses, with models featuring varying capacities and technologies.

Grain Dryer Models

There are many different grain dryer models on the market. The most commonly used models are:

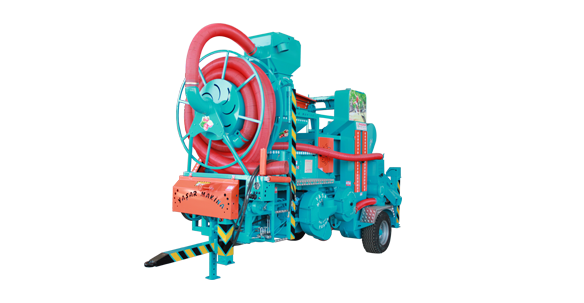

• Mobile grain dryers

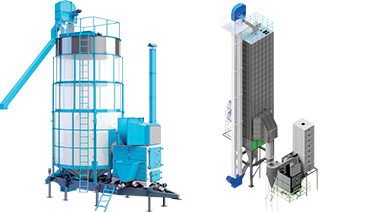

• Stationary system grain dryers

• Cylindrical drum grain dryers

• Grain dryers with automatic moisture control systems

• Low-temperature grain dryers

Each model is specifically designed for different needs and climatic conditions.

What Should You Consider When Choosing Grain Dryers?

• Capacity: Determine the daily amount of grain to be dried.

• Fuel Type: Choose from options such as electricity, natural gas, or diesel.

• Automation: Choose between fully automatic and manual models.

• Service and Spare Parts: Choose grain dryers from brands that offer after-sales support.

• Ease of Use: A user-friendly interface that operators can easily use is important.

Why Choose Our Grain Dryers?

Our company has been among the leading companies in agricultural technologies for years and has been producing high-quality grain dryers. With our engineering infrastructure and R&D expertise, we develop grain dryers to suit every need.

All our grain dryer models are CE certified and comply with energy efficiency standards. We also support our producers with technical service, installation, training, and spare parts support.

Protecting the Future with Grain Dryers

The future of agriculture depends on efficient and sustainable production. Grain dryers are a key component of this vision. To prevent crop losses, produce high-quality grain, and gain a competitive advantage, you should invest in modern grain dryer systems.

________________________________________

Grain dryers are not just machines; they are a production guarantee. If you want to preserve the value of your harvest and obtain long-lasting, high-quality grain, you're in the right place.

High-quality agriculture requires powerful equipment. Take your business to the next level with grain dryers.