High-Quality and Efficient Drying Solutions with Corn Drying Machines

22 Eylül 2025One of the most critical processes in the agricultural sector is product drying. Especially for products with high moisture content like corn, proper drying directly impacts yield. Corn dryers are a crucial aid for producers in this regard. Using them is crucial for both reducing product loss and achieving high-quality products.

What are Corn Dryers?

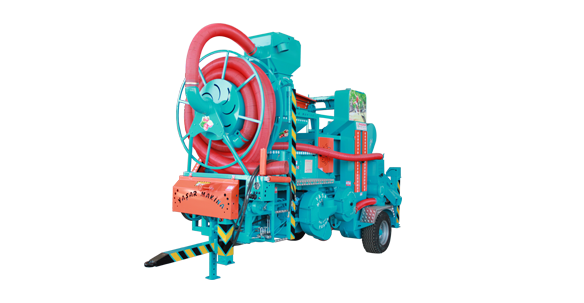

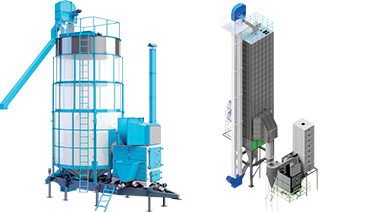

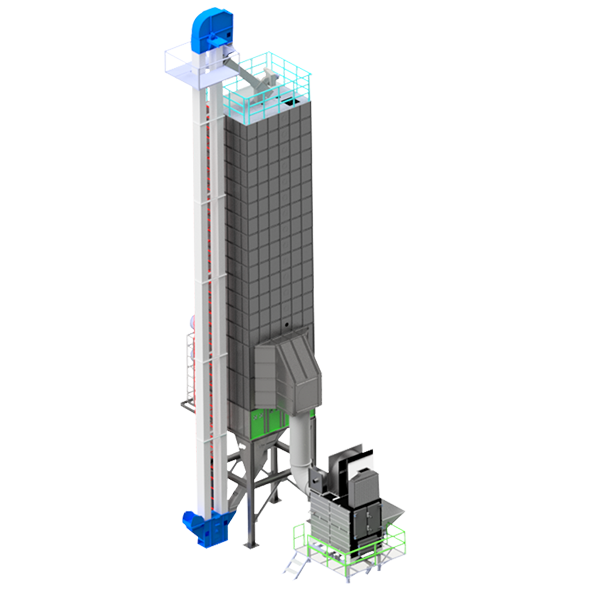

Corn dryers are modern agricultural machines that allow harvested corn to reach the desired moisture content. These machines allow corn to be stored for longer periods and be ready for sale. Today, thanks to technological advancements, corn dryers offer faster, more efficient, and safer drying options.

Why Use Corn Dryers?

• Increased Productivity: Advanced corn dryers, with their high capacity, dry more corn in a shorter time.

• Product Quality: With accurate temperature and humidity control, the corn's structure is preserved, preserving its nutritional value.

• Energy Savings: New-generation corn dryers operate with low energy consumption. • Time Savings: Provides much faster drying compared to traditional methods.

• Longevity: Robust and durable corn dryers provide high-performance operation for many years.

How to Choose the Most Suitable Corn Dryer?

1. Capacity: Choose a machine with the capacity that meets your daily drying needs.

2. Fuel Type: Choose between electric, diesel, or biomass-powered corn dryers based on your needs.

3. Mobility: Consider fixed or portable corn dryer options.

4. Automation: Automatically control temperature, humidity, and time, making corn dryers user-friendly.

5. Service and Support: Corn dryers from companies with a reliable service network should be chosen.

A Revolution in Agriculture with Corn Dryers

Traditional drying methods result in both time loss and a decrease in product quality. However, corn dryers provide homogeneous drying and guarantee that each corn kernel is dried evenly. This helps you achieve quality standards in both the domestic and export markets.

Corn Dryer Prices

There are many corn dryer models on the market with different features and capacities. Prices vary depending on the machine's capacity, fuel type, and automation level. For long-term savings, energy-efficient and low-maintenance corn dryers should be preferred.

The Most Preferred Corn Dryers in Turkey

Farmers across Turkey use corn dryers for high yield and quality. Domestically produced corn dryers are both cost-effective and offer access to technical support. These machines are particularly popular in the Black Sea, Thrace, and Central Anatolia regions.

Check Points for Corn Dryers

• Drying time and temperature must be automatically controlled.

• Corn dryers must be CE certified and comply with agricultural machinery regulations.

• Spare parts and service support must be fast and available.

• Corn dryers equipped with dust and particle filtration systems are environmentally friendly. Conclusion: The Right Investment – Corn Dryers

Corn dryers are an essential investment for any producer looking to improve quality and yield in corn production. A good choice not only provides greater profits but also a less stressful harvest season. With advanced, reliable, and durable corn dryers, you too can make a difference in agriculture.