Get Perfect Rice with Water Polishing Machines

22 Eylül 2025One of the most decisive factors in quality and hygiene in the food and agricultural industry is the polishing phase of the processed product. Water Polishing Machines, one of the most preferred equipment in this field, stand out in the industry with their high performance and effective cleaning properties. They increase both efficiency and the quality of the final product, and are indispensable for modern production.

What are Wather Polishing Machines?

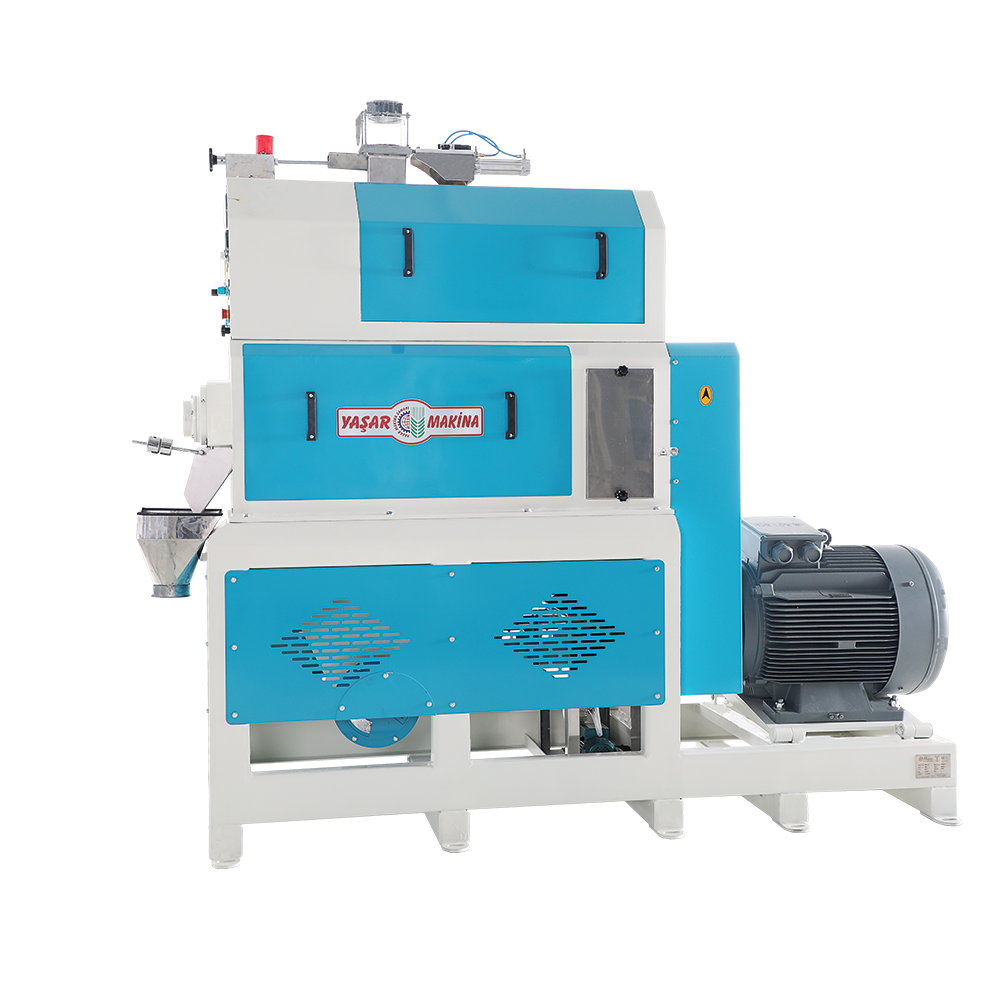

Watched Polishing Machines are specialized machines that remove dust, hulls, bran, and other residues from the surface of the product using a water-assisted mechanical system, achieving a shiny and smooth surface. Water Polishing Machines are particularly widely used in the processing of rice and similar grain products.

Why Choose Water Polishing Machines?

• Hygienic Cleaning: They provide a healthier and more sterile polishing process thanks to the use of water.

• Increased Shine: Increases the marketability of the product.

• Dust-Free Operation: Reduces dust in the environment, contributing to worker health.

• Energy Efficiency: New-generation Wet Polishing Machines operate with low energy consumption.

• High Performance: Able to polish a large quantity of products in a short time.

How Do Water Polishing Machines Work?

Water polishing machines process products using rotating drums or brushes, while a water spray system is activated simultaneously. This allows the product to be physically abraded and surface residue to be removed by the water. Water polishing machines can be equipped with different pressure settings and automatic water control systems.

Where Are Water Polishing Machines Used?

• Rice processing plants

• Corn and wheat polishing units

• Agricultural product cleaning stations

• Industrial food production plants

Water polishing machines, with models suitable for businesses of all sizes, have a wide range of applications.

Water Polishing Machine Models

There are many Wet Polishing Machine models on the market designed to meet different needs. These include:

• Automatic Water Polishing Systems

• High-capacity industrial models

• Compact and portable Water Polishing Machines

• Energy-efficient systems

• Models with adjustable pressure and water control

You can achieve maximum efficiency by choosing the right model for your business's capacity.

What to Consider When Buying Water Polishing Machines?

• Machine capacity and production volume

• Material quality (stainless steel should be preferred)

• Water consumption rate and recycling systems

• Automatic cleaning and ease of maintenance

• Technical service and spare parts support

The right choice of Water Polishing Machines reduces production costs in the long term while improving product quality.

Use of Water Polishing Machines in Turkey

Rice producers in Turkey, particularly in the Thrace, Marmara, and Black Sea regions, use Water Polishing Machines for efficient and hygienic production. Increasing export demands and food safety standards are making the use of Water Polishing Machines increasingly widespread.

Water Polishing Machine Prices

Prices for Water Polishing Machines vary depending on the machine's capacity, manufacturer's brand, additional features, and service warranty. These machines, with their short return on investment, are an ideal choice for producers seeking high quality standards.

________________________________________

Conclusion: Water Polishing Machines for Quality Production

Success in the food processing industry begins with the right equipment investment. Water Polishing Machines both improve product quality and add prestige to your business. If you want to produce brighter, cleaner, and higher-quality products, it's time to explore the solutions offered by Water Polishing Machines.

Water Polishing Machines are the best choice for modern production!