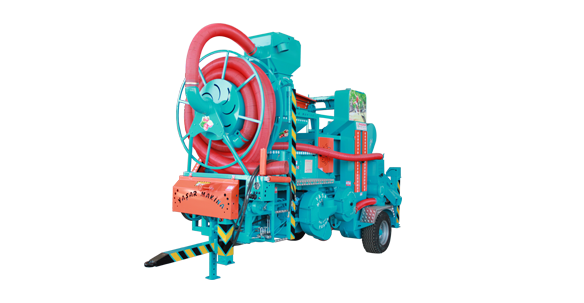

AUTOMATIC RICE MIXING SYSTEM - CONTROLLED BY PLC

PLC

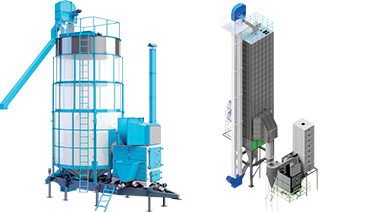

The rice mixing conveyors placed under the product storage bunkers in the facility to be packaged are used to make the desired product mixture according to the values entered by the operator's PLC control unit. The mixing system can be entered by giving the total Kg / Hour and by specifying the % ratios or by giving Kg / Hour directly from each material. This allows the product to be mixed as desired. Generally rice, wheat, barley, rye, oats, rice, lentils, corn, etc. It is designed to make a mixture in desired proportions for granular products on the basis of % in the package. There is a flow system controlled by an electric servo motor. Servo motors are integrated with the PLC control unit, giving the most accurate result with stable command loading. Dust-free rice mill, rice and paddy processing machines.

PLC controlled automatic dosing system is a type of automation equipment used in precise material dosing operations. PLC controlled automatic dosing system is a type of automation equipment used in precise material dosing operations. This system, which can operate automatically, increases efficiency in production processes and minimizes human errors.